Seramik Pota Leco 528-018. LECO CS230 için karbon kükürt pota ve cs pota üreticisi . Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO 5 28-018/002-301/002-302 Elementar 905.200.380.001 AN . Karbon kükürt Analiz Cihazı Element Analizi için kullanılır.

Devamını oku...

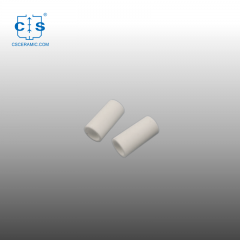

Her iki tarafı açık alüminyum borular , çeşitli endüstriyel ve laboratuvar uygulamalarında yaygın olarak kullanılmaktadır . _ Isıtma , soğutma ve kurutma gibi işlemlerde kullanım için idealdirler ve üstün termal ve elektrik yalıtımı sunabilirler . _ _ _ _ _ _ _

Devamını oku...

Bone Ash Cupels ile benzersiz saflık seviyelerine ulaşın. Safsızlıkları ve istenmeyen elementleri gidermek için tasarlanan bu küpeler, değerli metallerinizin gerçek özünü çıkarmanızı sağlar.

Devamını oku...

Alüminyum Cer amic Substrate Sheet , yüksek performans , güvenilirlik ve dayanıklılık gerektiren uygulamalar için ideal bir seçimdir . _ _ _ _ Farklı uygulamalara uyacak şekilde çeşitli boyutlarda ve kalınlıklarda mevcuttur . _ _ _ _

Devamını oku...

Alümina boru avantajı: yüksek ısı direnci, iyi soğuğa dayanıklı ısı direnci, asit ve alkali korozyonuna karşı direnç . Uzun servis ömrü. OEM kabul edilir.

Devamını oku...

Bir lümina pota ve tekne, laboratuvar ve endüstriyel analizlerin yanı sıra metal ve ametal malzeme numune eritme işlemlerinde çılgınca kullanılmaktadır. Çeşitli boyut ve şekillerde mevcuttur.

Devamını oku...

Çember alümina seramik çubuklar, diğer seramiklere göre daha yüksek mukavemet/ağırlık oranına sahiptir ve daha hafif ve daha güçlü parçalar üretmek için kullanılabilir. Çeşitli boyut ve şekillerde mevcuttur.

Devamını oku...

952018.906 TA Instruments TA Q500/Q50/TGA 2950/2050 için 100μl Platin/Pt Potalar ( Numune Tavaları) . TA krozeleri ve DSC numune kapları üreticisi . TA Instruments tga analiz cihazı iyi bir alternatif numune kapları.

Devamını oku...

ME-00024123 Mettler TGA/numune robotu ölçümleri için DSC Alümina potası numune kefeleri. Mettler Toledo potaları, numune kapları ve dsc sarf malzemeleri üreticisi .

Devamını oku...

LECO, Alpha AR9047 için 20 ml Büyük Seramik Pota 529-047 / 621-331 . LECO TGA 500/501/601/701, MAC 400 / 500 için TGA seramik pota üreticisi . TGA -Termogravimetrik Analizör analizi TGA ölçümü için TGA alümina potası / tavaları .

Devamını oku...eşya yok. :

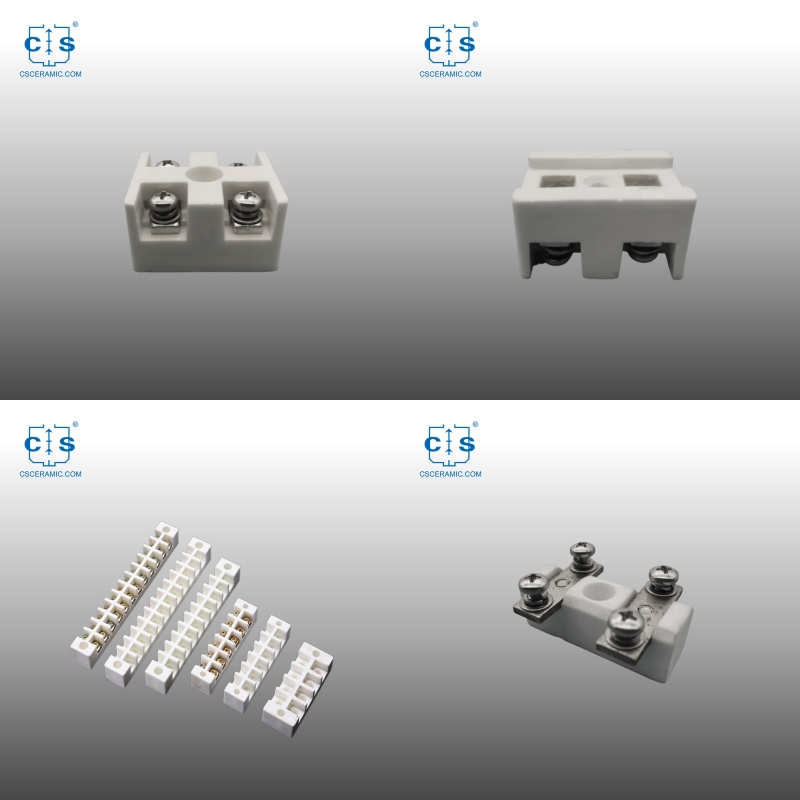

CS-AM1-00190% 92% 95% 99.5% 99.7% 99%

Material : Alumina ceramic

Shape : OEM

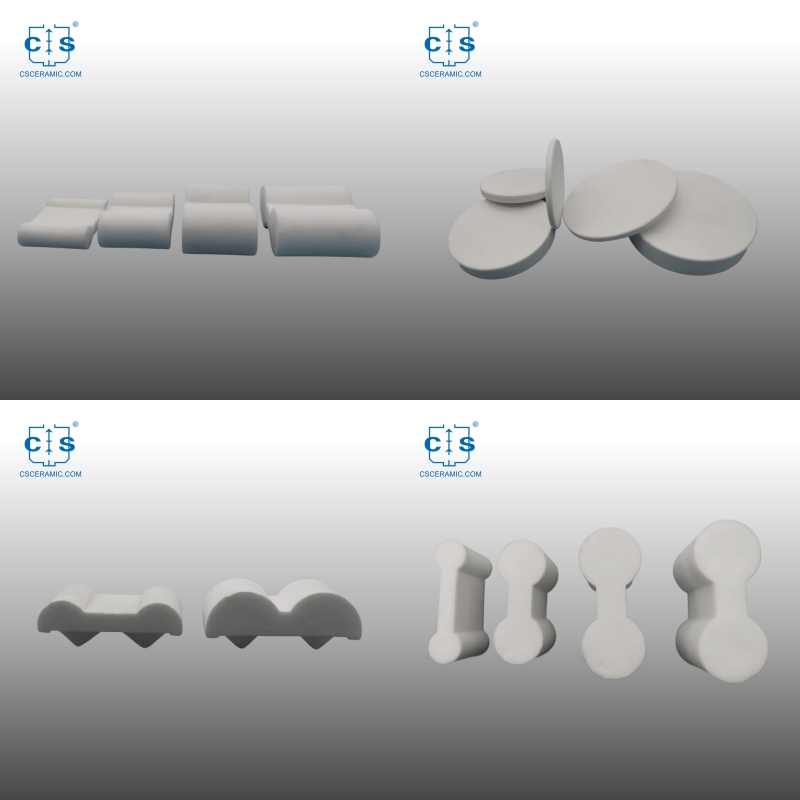

Advantages of alumina ceramic parts:

1. High Hardness: Alumina ceramic parts are known for their high hardness, making them ideal for use in high-wear applications.

2. Electrical Insulation: They provide excellent electrical insulation, making them ideal for use in electronic components and insulators.

3. Low Thermal Expansion: They have a low thermal expansion coefficient, meaning they do not expand or contract much with changes in temperature. This makes them ideal for use in applications where dimensional stability is critical.

4. Wear Resistance: They are highly wear-resistant and can withstand abrasive wear without deteriorating or losing their shape.

5. Good Machinability: Alumina ceramic is easy to machine, allowing for precise tolerances and complex shapes to be achieved.

6. Cost-Effective: They offer excellent performance at a relatively low cost compared to other high-performance materials such as metals or composites.

7. Environmental Stability: They are stable in a variety of environmental conditions, including exposure to UV radiation, humidity, and atmospheric pollution.

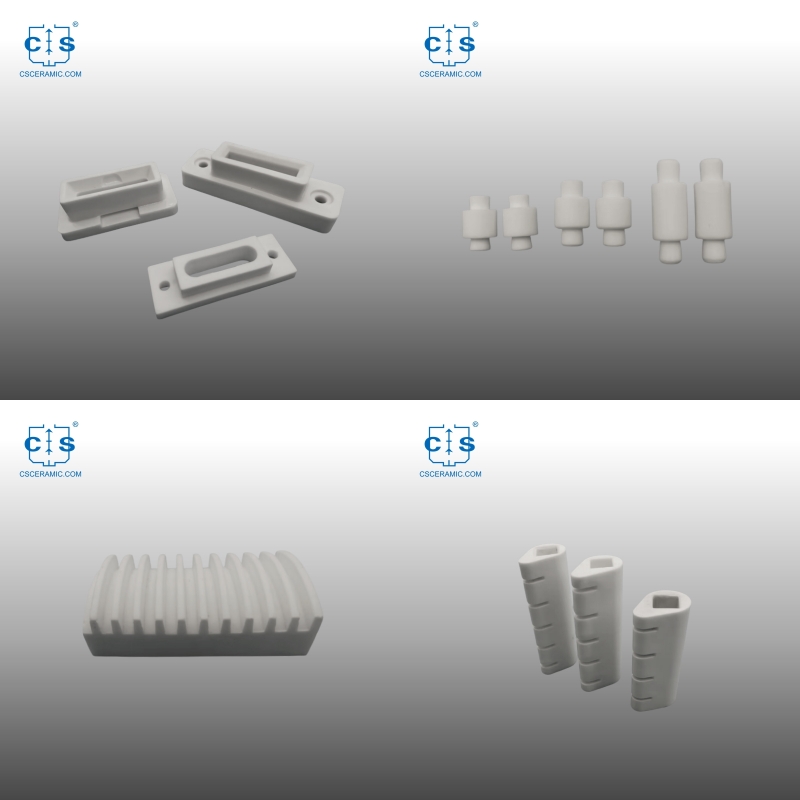

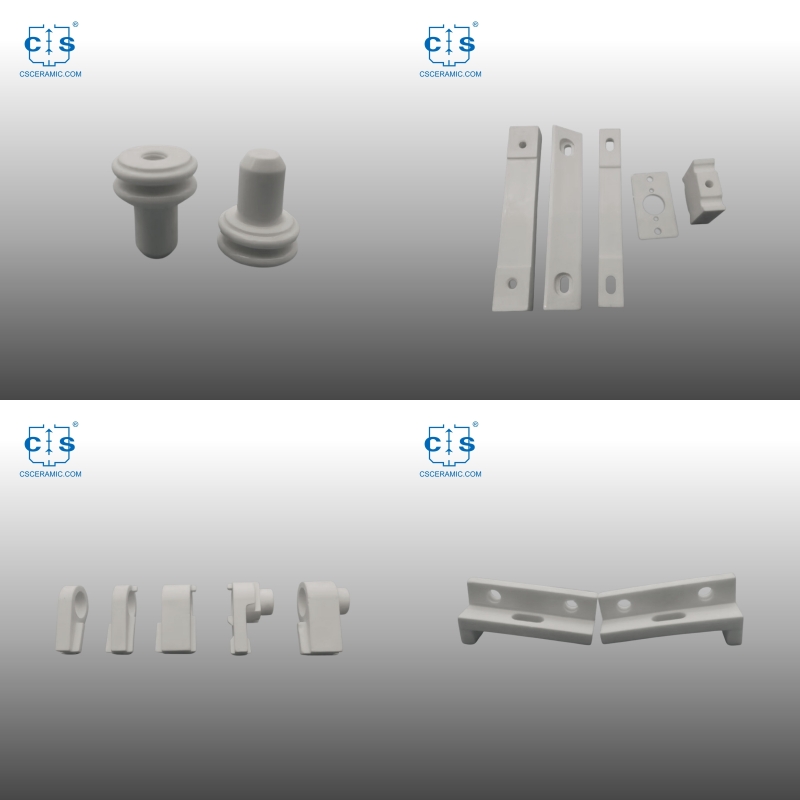

Descriptions of alumina ceramic parts:

1. Alumina ceramic parts are made from a material called alumina, they are typically used in industrial applications.

2. Some common alumina ceramic parts include ball bearings, insulators, and seals. Ball bearings made from alumina ceramic are used in high-speed machinery, while insulators and seals are used in electrical equipment because of their high electrical resistance.

3. They have a number of advantages over other types of materials.

4. They are an excellent choice for anyone looking for a durable and reliable material that can withstand even the toughest conditions.

5. Whether you need parts for industrial equipment or electrical systems, alumina ceramic is a great option that can deliver the performance and durability you need.

Size details:

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry

Parameters of Alumina Ceramic:

| Item | Test Condition | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | ||

| Physical properties | Density | g/cm3 | >3.6 | 3.89 | 3.96 | |

| Moisture absorption | % | 0 | 0 | 0 | ||

| Mechanical properties | ROHS Hardness | ≥85 | ≥89 | ≥89 | ||

| Flexural strength | psiX103 | 20℃ | 358 | 550 | 550 | |

| Compressive strength | psiX103 | 20℃ | 2068(300) | 2600(377) | 2600(377) | |

| Fracture toughness | Mpa.m3/2 | K(l c) | 4.3 | 5.6 | 6 | |

| Thermal properties | Maximum use temperature | ℃ | 1450 | 1600 | 1650 | |

| Thermal expansion coefficient | 1X10-6/℃ | (25-1000℃) | 7.6 | 7.9 | 8.2 | |

| Thermal shock resistance | ℃ | Tc | 250 | 200 | 200 | |

| Thermal conductivity | w/mok | 20℃ | 16 | 30 | 30.4 | |

| Electrical properties | Volume resistivity | Ohm/cm2 | 100℃ | >1013 | >1014 | >1014 |

| Dielectric breakdown strength | KV/mm | 8.7(220) | 8.7(220) | 8.7(220) | ||

| Dielectric constant | (E) | 1MHz25℃ | 9 | 9.7 | 9.7 | |

| Dielectric constant (100MHz) | (E) | 9.5 | ||||

Applications of alumina ceramic parts:

1. Electronic components: Alumina ceramic parts are used as substrates, insulators, and heat sinks for electronic components such as microchips, circuit boards, and power modules. These components require high thermal conductivity and excellent insulation properties to ensure efficient operation and to prevent damage due to heat buildup.

2. Medical implants and prosthetics: Used for the production of medical implants and prostheses.

3. Chemical processing: AUsed in chemical processing applications due to their resistance to corrosion, high temperatures, and abrasion. These parts can be used in valves, pumps, and pipes, among others, where the harsh chemical environment can cause damage to steel and other materials.

4. Aerospace and defense: These parts can be used in components such as radar systems, missile nose cones, and aircraft engine components.

5. Automotive components: Used in the production of automotive components, particularly in diesel engines due to their thermal shock resistance and improved fuel efficiency. These parts can be used in components such as diesel engine glow plugs, turbocharger bearings, and exhaust gas sensors.

6. Machinery components: Used in the production of machinery components, particularly those that require high strength and wear resistance. These parts can be used in components such as pump seals, bearings, and cutting tools.

7. Thermal spray coatings: Alumina ceramic parts can also be used as thermal spray coatings to provide increased wear resistance and thermal insulation. These coatings are commonly used in components such as turbine blades, aerospace applications, and automotive engine components.

FAQ

Q1. What information should we supply to get a quote?

Please offer the specification of alumina ceramic crucible, such as shape, dimension, quantity, application etc.

Q2. What applications are alumina ceramic parts suitable for?

Alumina ceramic parts are suitable for a wide range of applications, including medical implants, electronic components, automotive parts, cutting tools, and wear-resistant parts for machinery.

Q3. What sizes and shapes are available for alumina ceramic parts?

Alumina ceramic parts are available in a wide range of sizes and shapes, including rods, tubes, plates, discs, and custom shapes.

Q4. How long do alumina ceramic parts last?

Alumina ceramic parts have a long service life and can last for decades when used in the right applications. Their wear resistance and hardness make them ideal for applications where components are exposed to high levels of stress and wear.

Q5. Are alumina ceramic parts recyclable?

Alumina ceramic parts are not currently recyclable due to their high melting point and resistance to chemical corrosion. However, efforts are being made to develop new methods for recycling these parts in the future.

How to clean alumina ceramic parts:

1. Wear caring gloves and refuge glasses.

2. Use a soft cloth to remove any dust and dirt from the part.

3. Fill the part with warm up water and a mild detergent.

4. Scrub up the part with a soft brush to remove whatever residue.

5. Wash the part with clean water and allow it to dry out completely earlier use.

Quality testing standards:

1. Visual inspection of the part for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the part to check for accuracy.

3. Checking for any leaks or pinhole defects in the part.

4. Verification of the material and chemical composition of the part.

Packing way:

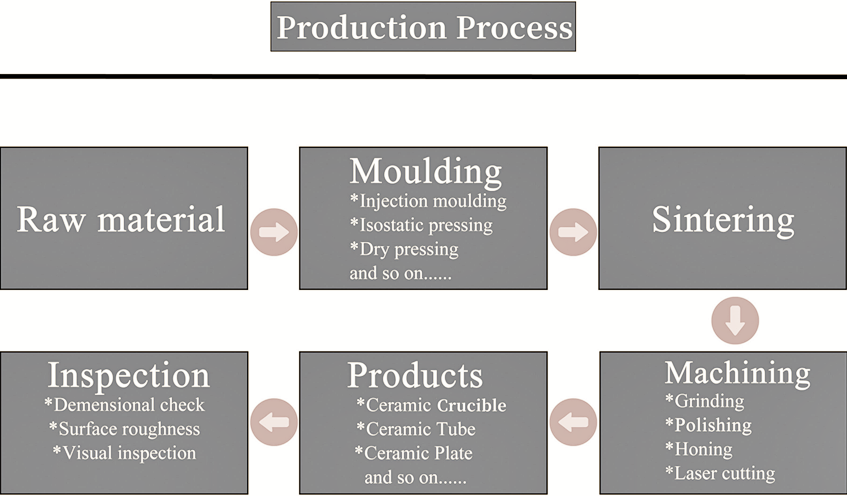

Üretim süreci:

Neden bizi seçmelisiniz?

1. Kişisel ihtiyaçlarınızı karşılamak için kişiselleştirilmiş ve özelleştirilmiş hizmetler sunuyoruz.

2. Bizler, iyi bir başarı siciline sahip deneyimli profesyonelleriz.

3. Üstün müşteri hizmeti sağlıyoruz ve tüm sorulara derhal yanıt veriyoruz.

4. Militan fiyatlar sunuyoruz ve fonlarınızın en iyi değeri almasını sağlamaya çalışıyoruz.

5. Projenizin en yüksek standartlarda tamamlanmasını sağlamak için en son teknolojileri ve araçları kullanıyoruz.

Daha fazla şekil :

Yüksek Mekanik Mukavemetli Alümina Steatit Seramik Parçalar

Yüksek Mekanik Mukavemetli Alümina Steatit Seramik Parçalar

Tablo kimyasal özelliklerine sahip alümina steatit seramik, yüksek sıcaklık direncinde mükemmel performans, iyi aşınma performansı ve korozyon direnci gösterir . Seramik bileşen tedarikçisi.

Alümina Seramik Termokupl İzolatör Tüpleri

Alümina Seramik Termokupl İzolatör Tüpleri

Yüksek aşınma ve darbe direncine sahip seramik izolatör borular , mükemmel korozyon direnci. Seramik bileşen tedarikçisi.

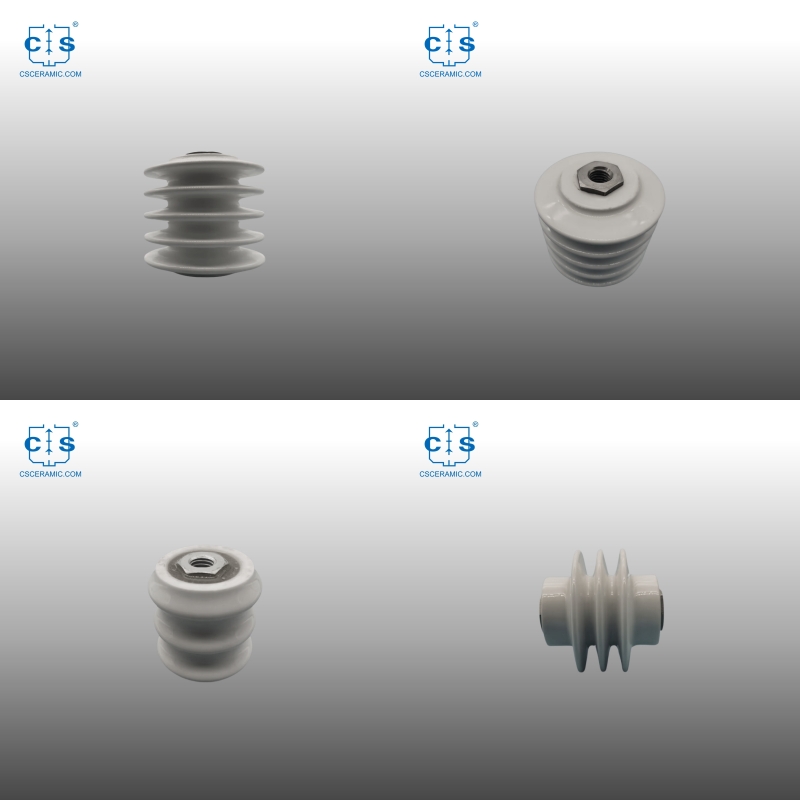

Alümina Burçlu Seramik İzolatör

Alümina Burçlu Seramik İzolatör

Kablo sonlandırmaları için Alümina Burçlu Seramik İzolatör .Çoklu yivli ve kapaklı burçlar, yeniden girişli burçlar, boru şeklindeki burçlar, namlu ve silindirik burçlar vb. özelleştirilebilir.

Alümina Seramik Rulman Seramik Burçlar

Alümina Seramik Rulman Seramik Burçlar

Yüksek verimliliğe ve hafifliğe sahip alümina seramik bilyalı yatak ve burç , aşırı sertliğe ve aşınmaya, ısıya ve korozyona karşı iyi dirence sahiptir. Çin için bir seramik rulman tedarikçisi.

Endüstriyel Seramik Piston Parçaları

Endüstriyel Seramik Piston Parçaları

Seramik piston , modern mühendislik seramik malzemelerinin ultra sert aşınma direncini benimser ve seramik metalleştirme yapıştırma, kaynak, dolgu ve soket teknolojisi ile birleştirilebilir.

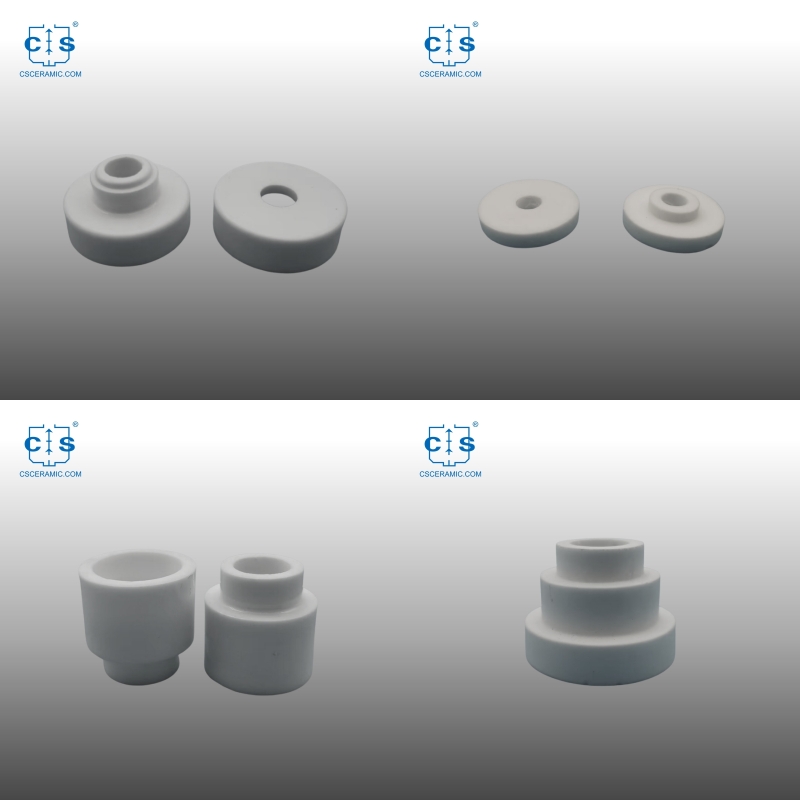

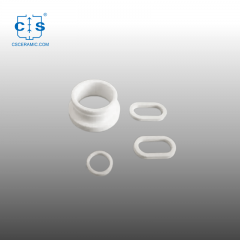

Yüksek Alümina Seramik Sızdırmazlık Yıkayıcı Seramik Conta

Yüksek Alümina Seramik Sızdırmazlık Yıkayıcı Seramik Conta

Yüksek sıcaklıkta aşınmaya, ısıya ve korozyona karşı mükemmel dirençli alümina yıkayıcı seramik conta . İzolatör yıkayıcı tedarikçisi.

%95 ila %99 Alümina Seramik Yıkayıcı Seramik Conta Halkası

%95 ila %99 Alümina Seramik Yıkayıcı Seramik Conta Halkası

Alüminyum onun seramik conta halkasıydı ve çeşitli uygulamalar için conta olarak kullanılıyordu . _ _ _ _ Bu halkalar, zamanla sızıntı yapmayan veya bozulmayan sıkı, güvenilir bir sızdırmazlık sağlamak üzere tasarlanmıştır. Tüm boyutlar özelleştirilebilir.

Yüksek Aşınma Direnci Alümina Seramik Yıkayıcı Sızdırmazlık Halkası

Yüksek Aşınma Direnci Alümina Seramik Yıkayıcı Sızdırmazlık Halkası

Seramik sızdırmazlık halkası , çeşitli uygulamalar için conta olarak kullanılıyordu . _ _ _ Bu halkalar, zamanla sızıntı yapmayan veya bozulmayan sıkı, güvenilir bir sızdırmazlık sağlamak üzere tasarlanmıştır. Tüm boyutlar özelleştirilebilir.

profesyonel ekip hizmet !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522